LARGE FORKLIFT FORKS

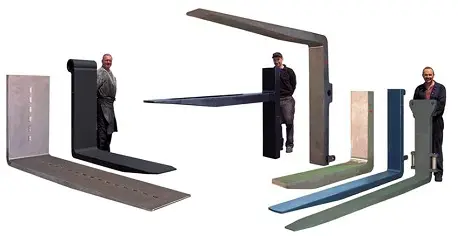

Large Forklifts range from 17,000 lbs. up to 80,000 lbs., and sometimes even above. Due to their variety and flexibility, Large Forklifts’ forks have different types of suspension devices.

The most popular Large forklift forks are:

- Pin Type Forks

- Terminal West Forks

- Class 5 ITA/Hook Forks

- Roller Forks

Pin type, Terminal West and Roller Forks don’t follow any dimension or carriage fitting standard.

See below OUR MOST POPULAR LARGE FORKS

UP TO 96" LENGTH IN-STOCK FOR QUICK DELIVERY

- Pin Type Forks

- Terminal West Forks

- Class 5 Hook Forks (Standard ITA)

- Roller Forks

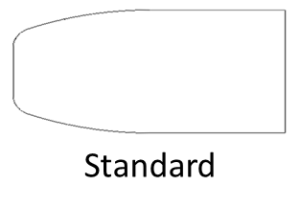

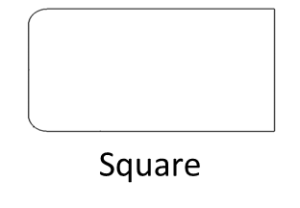

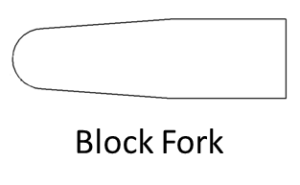

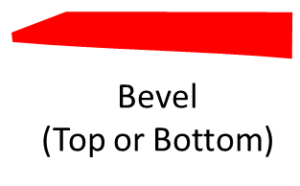

- Blade options

- Tip options

- Pin Type Forks

- Pin type forks are hanged to the truck carriage using a welded tube/pin.

Tube/pin fork dimensional tolerances and position are unique for each model and type of truck.

- Common section sizes in-stock for quick delivery, up to 96” length:

- – 2.3×6”: capacity per pair 18,000 lbs @ 24” load center

- – 2.5×6”: capacity per pair 21,000 lbs @ 24” load center

- – 3.0×7”: capacity per pair 35,000 lbs @ 24” load center

- – 3.5×7”: capacity per pair 47,000 lbs @ 24” load center

- – 3.0×8”: capacity per pair 40,000 lbs @ 24” load center

- – 3.5×8”: capacity per pair 54,000 lbs @ 24” load center

- – 4.0×8”: capacity per pair 67,000 lbs @ 24” load center

- – 4×10”: capacity per pair 84,000 lbs @ 24” load center

- The documents below can help you to select your Pin Fork:

- Pin Type Fork Spec Sheet

- Pin Position 3-Steps Guide

- Capacity Chart

Contact us for other section sizes and options.

- The capacity per pair must be equal or greater than your truck capacity.

- For heavy applications, please consider a higher capacity fork.

- Terminal West Forks

Terminal West forks are hanged to the truck carriage using a square top hook and lower brackets. TW forks dimensional tolerances and position are unique for each model and type of truck.

- Common section sizes in-stock for quick delivery, up to 96” length:

- – 2.3×6”: capacity per pair 18,000 lbs @ 24” load center

- – 2.5×6”: capacity per pair 21,000 lbs @ 24” load center

- – 3.0×7”: capacity per pair 35,000 lbs @ 24” load center

- – 3.5×7”: capacity per pair 47,000 lbs @ 24” load center

- – 3.0×8”: capacity per pair 40,000 lbs @ 24” load center

- – 3.5×8”: capacity per pair 54,000 lbs @ 24” load center

- – 4.0×8”: capacity per pair 67,000 lbs @ 24” load center

- – 4×10”: capacity per pair 84,000 lbs @ 24” load center

- The documents below can help you to select your TW Fork:

- Terminal West Spec Sheet

- Big Forks Brochure

- Capacity Chart

- Contact us for other section sizes and options.

- The capacity per pair must be equal or greater than your truck capacity.

- For heavy applications, please consider a higher capacity fork.

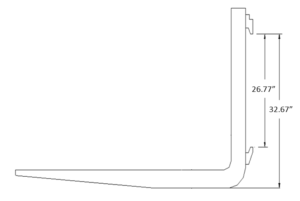

- Class 5 ITA/Hook Forks

- Class 5 ITA/Hook forks are set based on truck capacity and carriage size per ANSI B56.11.4.

- Capacity: 17,501 – 24,000 lbs

- Working Back Height (h1): 32.67″

- Distance Between Hooks (h2): 26.77″

- Common section sizes in-stock for quick delivery, up to 96” length:

- – 2.5×6”: capacity per pair 21,000 lbs @ 24” load center

- – 3.0×7”: capacity per pair 35,000 lbs @ 24” load center

- – 3.5×7”: capacity per pair 47,000 lbs @ 24” load center

- – 3.0×8”: capacity per pair 40,000 lbs @ 24” load center

- The documents below can help you to select your CL5 Fork:

- Big Forks Brochure

- ITA/Hook Fork Spec Sheet

- Capacity Chart

Contact us for other section sizes and options.

- The capacity per pair must be equal or greater than your truck capacity.

- For heavy applications, please consider a higher capacity fork.

- Roller Forks

- Roller forks are hanged to the truck carriage using top and/or bottom rollers. Roller forks dimensional tolerances and position are unique for each model and type of truck.

- Common section sizes in-stock for quick delivery, up to 96” length:

- – 2.3×6”: capacity per pair 18,000 lbs @ 24” load center

- – 2.5×6”: capacity per pair 21,000 lbs @ 24” load center

- – 3.0×7”: capacity per pair 35,000 lbs @ 24” load center

- – 3.5×7”: capacity per pair 47,000 lbs @ 24” load center

- – 3.0×8”: capacity per pair 40,000 lbs @ 24” load center

- – 3.5×8”: capacity per pair 54,000 lbs @ 24” load center

- – 4.0×8”: capacity per pair 67,000 lbs @ 24” load center

- – 4×10”: capacity per pair 84,000 lbs @ 24” load center

- The documents below can help you to select your Roller Fork:

- Big Forks Brochure

- Capacity Chart

- Due to their complexity, Roller forks are best selected by Fork part# or MSI production lot#.

- Contact us for other section sizes and options.

- The capacity per pair must be equal or greater than your truck capacity.

- For heavy applications, please consider a higher capacity fork.

Need help?