SAFETY

Serious accidents and equipment downtime can be prevented with proper fork sizing, inspection and operator training.

Forks are one of the most demanded items on a forklift and companies are usually not aware of their forks condition or quality.

Common Safety Questions

What, when, how?

Safety Standards

Are your forks regularly inspected in compliance to industry standards ISO 5057 or ANSI B56.1?

10% wear

Did you know that forks with 10% wear must be replaced and it is unsafe to use?

Training

Are your operators properly trained to understand critical concepts of load center and capacity?

Monitoring & Prevention

Are you monitoring fork replacements to prevent cyclic operational issues or accidents?

Appropriate forks

Are you using the correct forks for your application, capacity and blade length?

Per ISO 5057 and ANSI B56.1, forks in service must be inspected at least every 12 months!

Fork Safety & Inspection

Because these are very common questions, we have put together some guidelines below.

- Easy to avoid issues

- Inspection Frequency

- What to look for

- Technical Crack Testing

- Repair & Replace

The points below will significantly reduce the life of your forks:

– Handling loads above the fork’s capacity.

– Using only one fork to handle loads.

– Applying side pressure/force on the forks.

– Dragging the forks on the ground.

– Making unauthorized repairs or modification to the forks.

– Using the forks as a lever or crowbar to separate loads.

– Using the forks to push or pull dragging loads.

– Adding fork extensions longer than 30% of the fork original blade length.

Easily start by training your forklift operators to avoid these “unsafe” operational practices

Forks in service should be submitted to periodic visual and dimensional inspection. According to ISO 5057 and ANSI B56.1, the fork inspection intervals should not be more than 12 months.

MSI recommends the frequency as follows:

– For operations with 1 shift (up to 8 hours per day) = at least every 12 months.

– For operations with 2 shifts (up to 16 hours per day) = at least every 6 months.

– For operations with 3 shifts (up to 24 hours per day) = at least every 3 months.

The frequency should be increased in case of repetitive damage or severe working conditions.

Below are the main points that you need to pay attention when inspecting your forks.

1. Surface cracks: attention to all welds and internal heel area. Fork arms should be replaced if surface cracks are detected.

2. Blade deflection or Tip height: the difference of tip heights cannot exceed 3% of the blade length.

3. Marking legibility: fork identification according to ISO 2330 should be easily legible. In case of missing or unclear marking the fork should be removed from service.

4. Angle opening: the internal angle of the fork heel cannot exceed 93°.

5. Locking & suspension devices: check if forks are securely locked to the equipment carriage. In case of extra clearance or damaged attachments, the forks should be repaired.

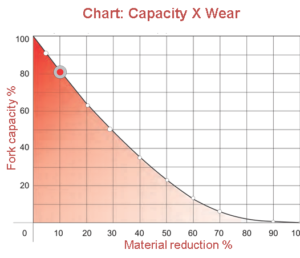

6. Wear: the material wear on the heel area of the forks cannot exceed 10% of the original section of the fork. Capacity of the fork is drastically reduced due to material wear. A 10% wear represents a 20% loss of capacity – see graph below:

Traditional crack detection tests:

– Contrast spray

– Magnetic particles

– Ultra-sound

The above tests should only be carried out after a visual and dimensional inspection of the forks is completed and a crack indication is suspected. Technical crack tests should be performed only by a trained professional. MPI (magnetic particles inspection) is the preferred method of ISO 2330 and ANSI B56.11.4.

Based on ISO 5057 and ANSI B56.1, at no circumstance surface cracks can be repaired by welding.

Defective forks should be promptly replaced or repaired to maintain the maximum safety and performance of your machinery.

Fork repairs can only be performed by the fork manufacturer or a certified company.

Always request the fork manufacturer authorization before carrying any modification or repair. Any modification performed without authorization will cancel the fork arm warranty.

Be sure to replace the pair of forks, not a single piece.

Download your Fork Safety & Inspection Guide

Following MSI's Fork Safety & Inspection Guide, will significantly reduce the risk of accidents.